What is the structure of the double shaft shredder

2022-03-17

Kowloon double shaft shredder is mainly used for crushing, shredding and shearing to downsize materials. It is commonly used in the environmental protection industry. Its main structure is composed of two shafts, blade, shredder chamber, gearboxes,control cabinet,and some models of dual shaft shredders with hydraulic press device as feeding assistant. The functions of its main components are as follows:

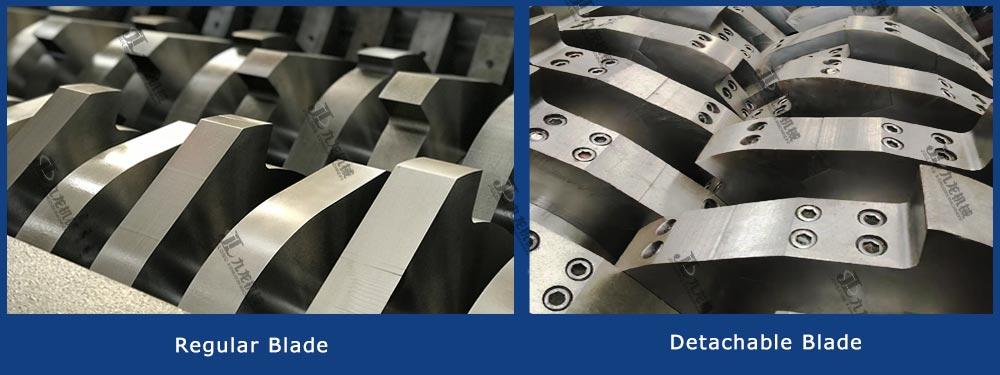

Detachable blades:

Kowloon shredders equipped with detachable blades,this design can greatly shorten the replacement time of the blade. A complete blade consists of blade core, changeable blade corners (claw on blade) and replaceable shearing blade (without corner for shearing) . The disassembly and replacement of worn blades can be easily completed by loosening and locking bolts. Shredding different materials, flexibly equipped with the corresponding number of blade corners, can give full play to the best tearing effect of the machine.Spline shaft:

The spline shaft is made of high alloy 42CrMo material, which can evenly transfer the torque to the blade, reduce the wear between the blade and shaft. Because the main diameter of spline and the diameter of shaft head are the same, it is more suitable for large shredder to shred hard metal materials.

Shredder chamber:

The shredder chamber can be removed from both ends of the coupling. The main shaft can be disassembled as a whole part after bearing case off. We can maintain,check or replace the blades and bearing after main shaft took off. Such simple design provide a safer working condition for user. The overall processing of shredder chamber ensures the concentricity of shafts and bearings installation position, also prolongs the service life of the bearing and gearboxes, and makes the machine run more smoothly.

Gearbox:

Equipped with planetary gearboxes, hardened gears are made of high-quality alloy steel, and the surface is carburized, quenched and hardened. Gear teeth is precision machined,ensure stable transmission, low noise, large bearing capacity, low temperature rise and long service life. Gearbox directly connected with motor can greatly improve transmission rate. The shaft coupling end of the gearbox adopts spline design, which can effectively transmit torque and reduce energy consumption. The maintenance is convenient, and the demolition, maintenance and other work can be realized with simple tools.

Feed assistant device:

The material pressing device is installed above the hopper and driven by the hydraulic system, which can squeeze the large volume of materials to the bottom of the crushing box, so that the blade teeth can tear up the materials and improve the output of the equipment. The modular design of hydraulic device simplifies the work flow of hydraulic oil replacement and other maintenance.

Control cabinet:

Kowloon electric control cabinet can be customized with Siemens PLC and Schneider electrical components to realize the operation automation of two shaft shredders. Touch screen control cabinet is optional, it makes the programming, maintenance and overhaul of the whole machine convenient. Customers can choose soft start or VFD frequency converter to start the machine smoothly.