Contact Us | +86 15649675999 | sale@kowloonmachine.com

HOME / Municipal Solid Waste Crusher Bulky waste Shredder machine

Low speed, high torque rotor, cutting and shearing working principle suitable for both soft and hard materials;

Blades made of special alloy, different shape, thickness and cutting head quantity providing the optimum solution for different materials.

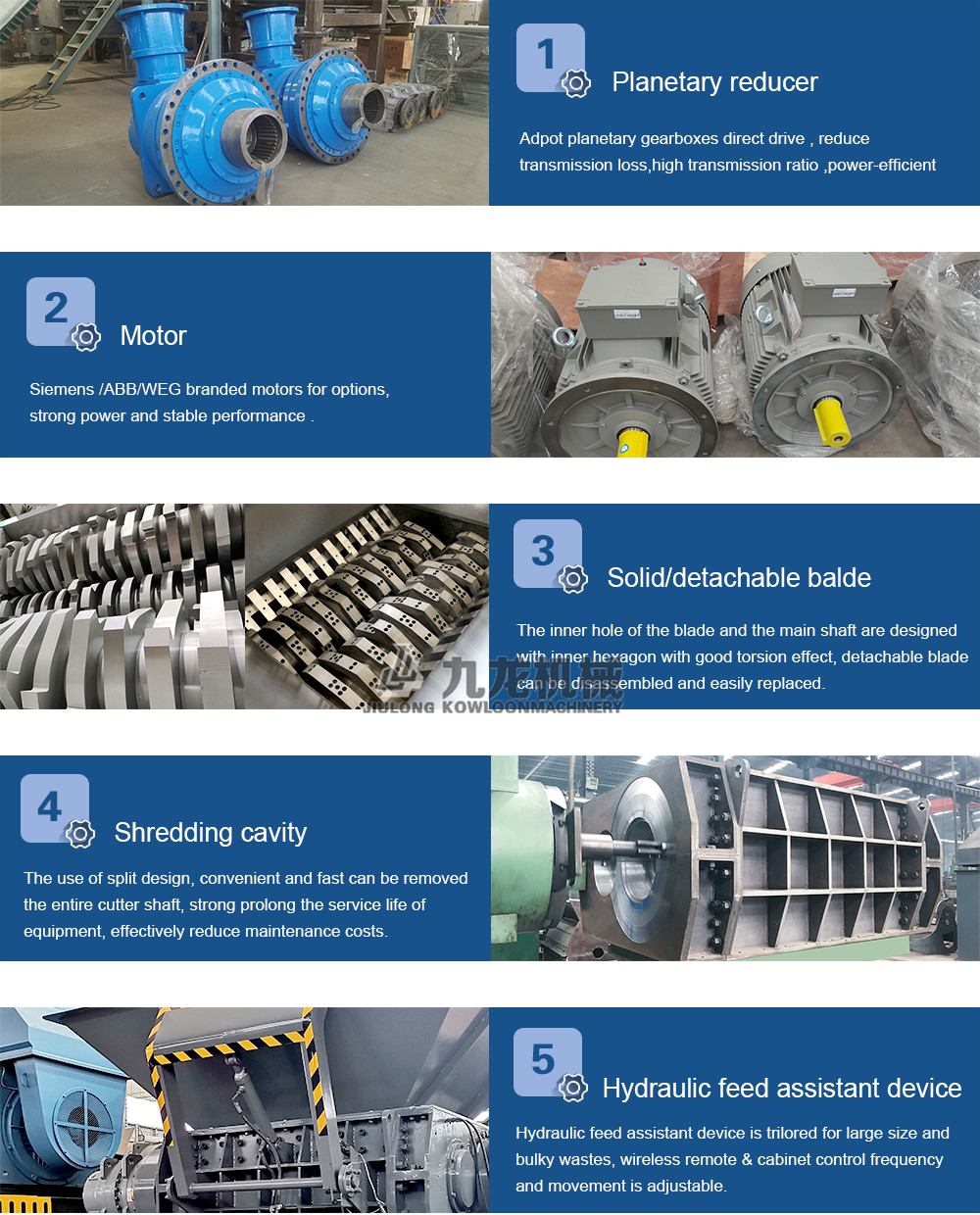

Siemens, ABB, WEG¡ etc quality motors are available for different customers's options

Schneider, Chint, Siements¡-etc electrical components to ensure steady performance and realize machine 24hours running, also PLC system is optional to enabling automatic reverse for overload protection and minimizing blades damages;

Individual electrical control panel with PLC control system ensure the machine work properly and safety;

Detachable type cutting head on shredder blades, makes the maintenance and replacement of wearing parts easier and much shorten maintenance time.

Low speed, lower noise, workable in workshop and outdoor

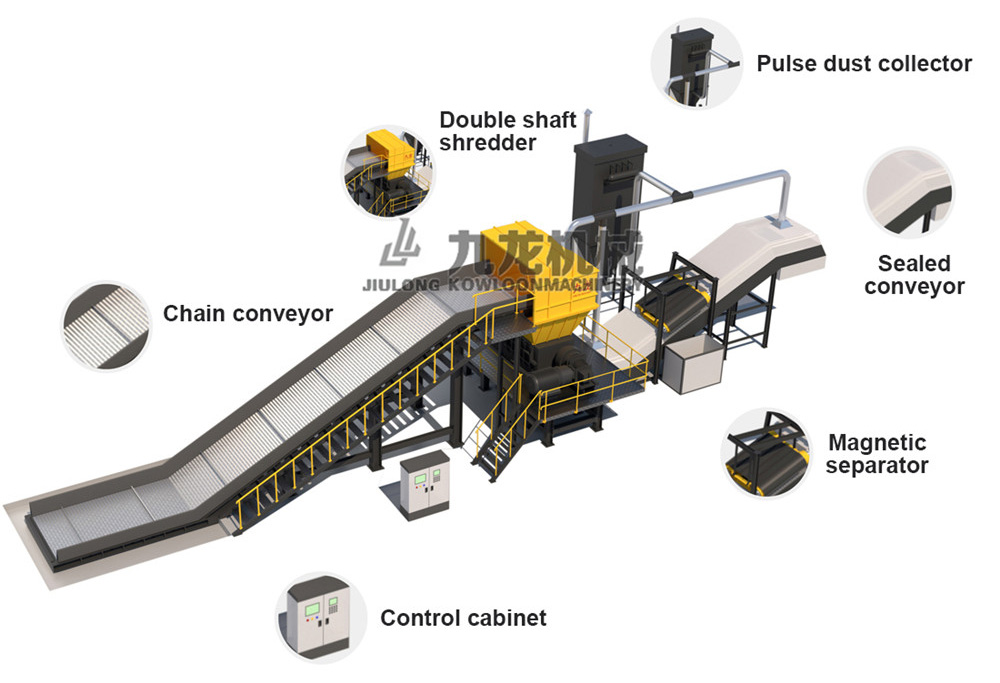

Municipal Solid Waste Crusher Bulky waste Shredder machine

The main material is IBC tank, plastic/metal barrel, waste furniture, sofa, mattress, home appliances and other large size materials, which inconvenient for transportation, Kowloon MSW furniture shredder specifically designed for such large pieces of garbage, can effectively solve this problem. In another way the shreds after processing can also be used for secondary resources recovery.

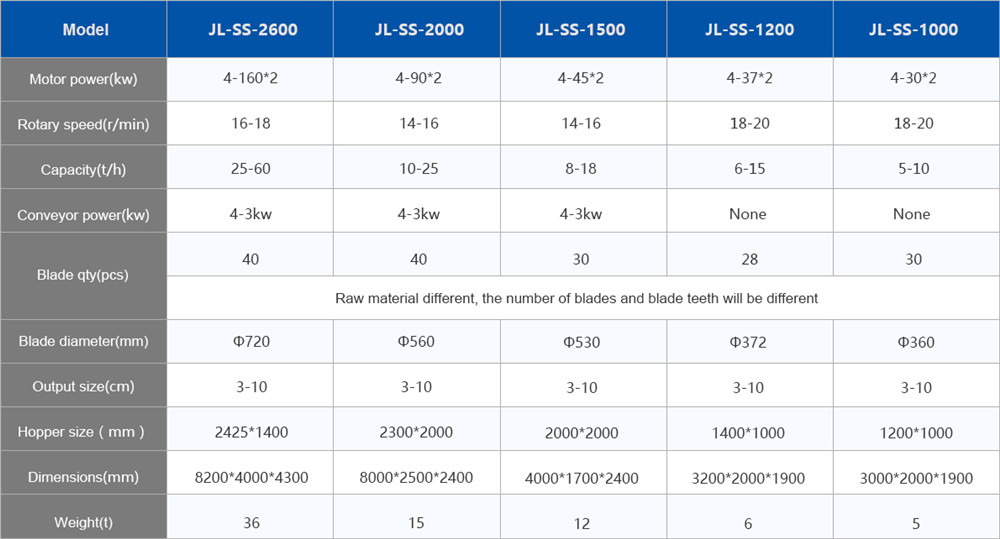

Technical parameter:

Features:

Low speed, high torque rotor, cutting and shearing working principle suitable for both soft and hard materials;

Blades made of special alloy, different shape, thickness and cutting head quantity providing the optimum solution for different materials.

Siemens, ABB, WEG¡-etc quality motors are available for different customers¡¡¡¡¡¡¡ì¬o¡¡¡¡¡ì¬¡¡¡¡ì¬ options

Schneider, Chint, Siements¡-etc electrical components to ensure steady performance and realize machine 24hours running, also PLC system is optional to enabling automatic reverse for overload protection and minimizing blades damages;

Individual electrical control panel with PLC control system ensure the machine work properly and safety;

Detachable type cutting head on shredder blades, makes the maintenance and replacement of wearing parts easier and much shorten maintenance time.

Low speed, lower noise, workable in workshop and outdoor

Application

1. Plastic: large head material, engineering plastics, paint barrels, glass

2. Appliances: TV sets, monitors, microwave ovens, dishwashers and other small and medium-sized home appliances shell, electrical equipment

3. Electronic products: computer host shell, hard drive, CD-ROM, battery shell

4. Pipe: PVC, PE, PP and other pipe, urban water supply pipe, drain pipe

5. Wood: logs, pallets. wooden board, piece of furniture

6. Rubber: waste car tires, conveyor belt

7. Metal: steel IBC cube, metal sheet such as copper, aluminum or iron, aluminum castings and crush blocks, motorcycles, car engine housings, oil filters

Delivery &Shipping for Twin Shaft Shredder

1.Plastic wraps to

protect wood shredder, tire shredder from dust, moisture and corrosion.

2. Wooden case for

compact machine or wearing parts as the outside package. Or according to the

customer requirements.

3.Excellant logistic

team to guarantee the shredder machines to be safely shipped to customer

warehouse, no extra fee on export or import on custom.

Kowloon Service

1.

Pre-sales: Provide fitted solution and offer to customers, is able to adjust

the layout of complete line to fit customers¡¡¡¡¡¡¡ì¬o¡¡¡¡¡ì¬¡¡¡¡ì¬ working area, also provide

technical support 24 hours service online.

2. After sales:

Kowloon skilled technicians are experienced at oversea installation, therefore

they are available to assist with onsite installation, commissioning &

training on request. Layout drawing, circuit diagram and maintenance manual

will be provided together with our products after sales, so that ensure

customers have plenty of time to get prepared for installation.

3. Wearing parts support

Kowloon has widely

built extensive cooperation with wearing parts partner manufacturers more than

14years, has ability to continuously provide wearing parts and after-sale

service to global market.

Company Introduction

Kowloon Machinery located in industrial hub of Zhenghzou city, China, design and manufacture industrial shredder, wood processing machinery, waste tire recycle equipment and scrap metal recycling machines. Kowloon products approved by CE and ISO certificates. Up to now, we have exported to more than 30 countries and share markets in worldwide, and now are still growing continuously.

We effort on improving and researching, in past years, various of new products were developed and becomes popular in domestic and abroad market, won good reputation and corporate image, we always effort on best quality and service, welcome to inquiry!

FAQ for double shaft shredder

1: Are You Trading Company or Factory?

Kowloon Machinery is a Factory with 31 years experience in machinery manufacturing; we provide you completive Factory Price and good After-sale Service!

2: What about the Machine Installation?

For a single machine or a simple line, we provide you Foundation Drawing ,Installation Instruction Books or successful installed machinery picture or video; for large machines and complex production line, we could send our engineers to guide the installation if necessary

3: How About the Spare Parts?

We offer some free spare parts like belt, gasket etc small parts, for the BLADES, KNIVES, SHAFTS etc important wearing parts, we suggest customers buy some along with the machines to save the shipping cost, and we have enough spares parts in stock.

4: What Will We Do If We Have Problems in Machine Working After We Buy the Machine?

Kowloon has people special for after-sale service,if customers outside China have problems when machine working, just feel free to send us the picture or video to show us, we will give you solutions in 24hours.

5: Could We Visit Your Factory and Test the Machine?

We warmly welcome you to visit our factory anytime, and we are very glad to test our machine with your raw material.