Contact Us | +86 15649675999 | sale@kowloonmachine.com

HOME / Waste car shredder vehicle recycle machine

Low speed, high torque rotor, cutting and shearing working principle suitable for both soft and hard materials;

Blades made of special alloy, different shape, thickness and cutting head quantity providing the optimum solution for different materials.

Siemens, ABB, WEG etc quality motors are available for different customers' options

Schneider, Chint, Siemens¡ etc electrical components to ensure steady performance and realize machine 24hours running, also PLC system is optional to enabling automatic reverse for overload protection and minimizing blades damages;

Individual electrical control panel with PLC control system ensure the machine work properly and safety;

Detachable type cutting head on shredder blades, makes the maintenance and replacement of wearing parts easier and much shorten maintenance time.

Low speed, lower noise, workable in workshop and outdoor

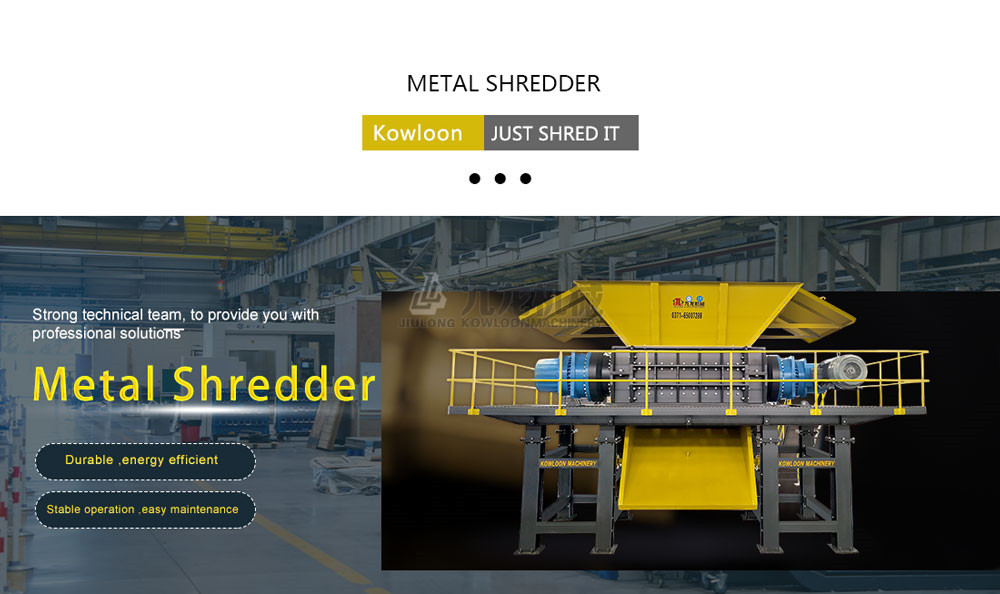

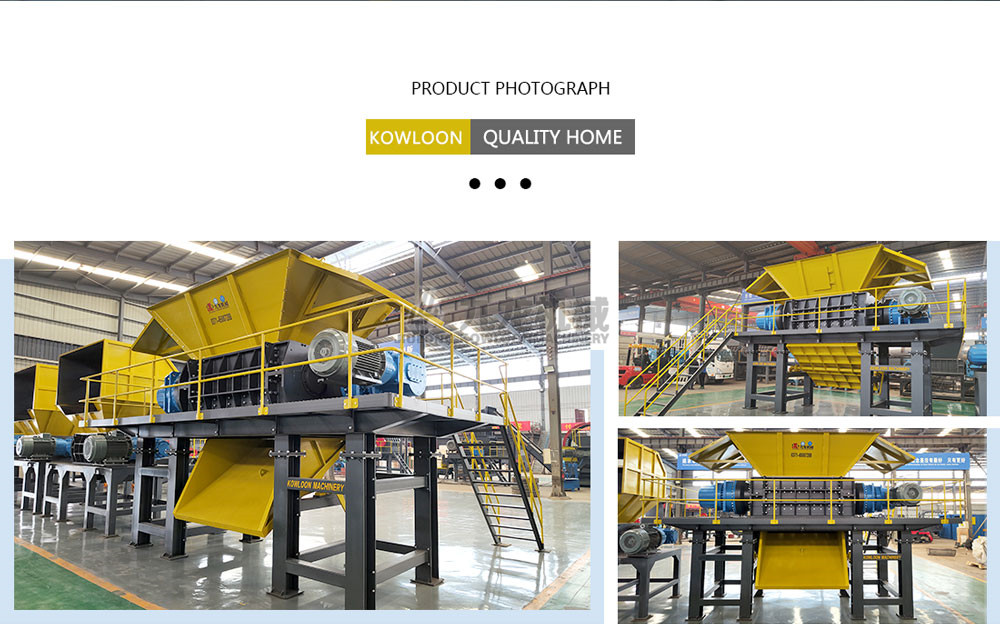

Waste car shredder vehicle recycle machine

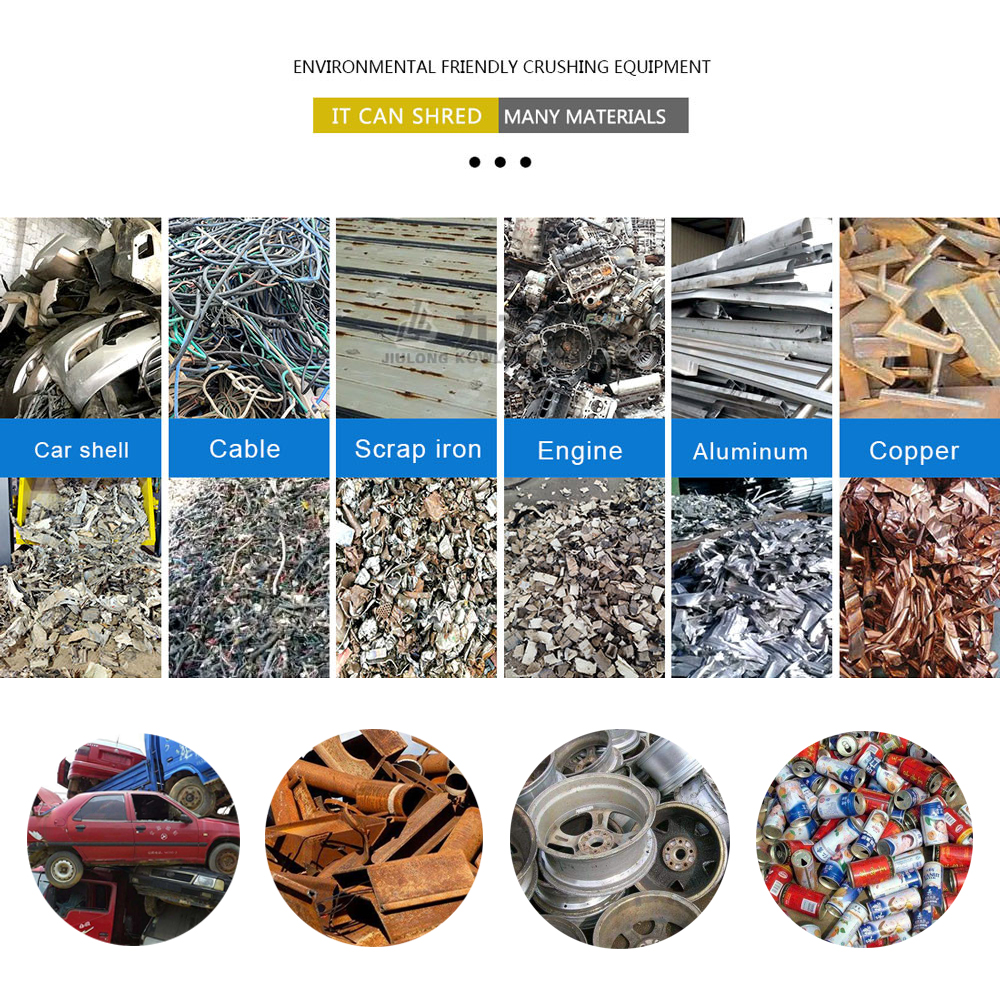

Scrap Metal Shredder is one metal pre-shredder, processing most heavy waste metal, such as whole car, aluminum/iron bundles, engine, thick iron plate, metal drum, motorcycle frame, etc. Kowloon metal shredder is equipped with planetary reducer of high torque, detachable blades, Siemens motors and electric cabinet, and other high configurations. Several such metal shredders have been exported to Poland, Romania, South Africa, Republic of Korea, Indonesia, Thailand, America, Mexico, etc.

Model

JLSS1200D

JLSS1500D

JLSS2000D

JLSS2600D

Motor

30kw+30kw

30kw+30kw/55kw+55kw

75kw+75kw/90kw+90kw

110kw+110kw/160kw+160kw

Gearbox

Gearbox: planetary type, gear transmission

Shaft

solid shaft, made of 40Cr, hardened and tempered

Shredder chamber (inner)

1120x1000mm

1450x1100mm

1920x1250mm

2425x1400

Rotor rotary speed

6-8rpm

6-8rpm

4-6rpm

4-6rpm

Blade type

Detachable type

Detachable type

Detachable type

Detachable type

Blade

Dia.530mm

Dia.530/560mm

Dia.730mm

Dia.730/900mm

Lubrication system

With automatic oil lubricator for gearboxes

Dimension

3.2x2x1.9m

4.04x2.45x2.6m

5.48x2.79x3.05m

7.74x4.12x4.72m

Weight

17000kg

22000kg

34000kg

58000kg

Features:

Low speed, high torque rotor, cutting and shearing working principle suitable for both soft and hard materials;

Blades made of special alloy, different shape, thickness and cutting head quantity providing the optimum solution for different materials.

Siemens, ABB, WEG quality motors are available for different customers' options

Schneider, Chint, Siemens¡-etc electrical components to ensure steady performance and realize machine 24hours running, also PLC system is optional to enabling automatic reverse for overload protection and minimizing blades damages;

Individual electrical control panel with PLC control system ensure the machine work properly and safety;

Detachable type cutting head on shredder blades, makes the maintenance and replacement of wearing parts easier and much shorten maintenance time.

Low speed, lower noise, workable in workshop and outdoor

Customer site:

Delivery &Shipping for Twin Shaft Shredder

1.Plastic wraps to protect wood

shredder, tire shredder from dust, moisture and corrosion.

2. Wooden case for compact machine or wearing parts as the outside package. Or

according to the customer requirements.

3.Excellant logistic team to guarantee the shredder machines to be safely

shipped to customer warehouse, no extra fee on export or import on custom.

Kowloon Service

1. Pre-sales: Provide fitted solution and offer to customers, is

able to adjust the layout of complete line to fit customers¡¡¡¡¡¡¡¡¡ì¬¬o¡¡¡¡¡¡¡ì¬¬¡¡¡¡¡¡ì¬¬ working area, also

provide technical support 24 hours service online.

2. After sales:

Kowloon skilled technicians are experienced at oversea installation, therefore

they are available to assist with onsite installation, commissioning &

training on request. Layout drawing, circuit diagram and maintenance manual

will be provided together with our products after sales, so that ensure

customers have plenty of time to get prepared for installation.

3. Wearing parts

support

Kowloon has widely built extensive cooperation with wearing parts partner

manufacturers more than 14years, has ability to continuously provide wearing

parts and after-sale service to global market.

Company Introduction

Kowloon Machinery located in

industrial hub of Zhenghzou city, China, design and manufacture industrial

shredder, wood processing machinery, waste tire recycle equipment and scrap

metal recycling machines. Kowloon products approved by CE and ISO certificates.

Up to now, we have exported to more than 30 countries and share markets in

worldwide, and now are still growing continuously.

We effort on improving and researching, in past years, various of new products

were developed and becomes popular in domestic and abroad market, won good

reputation and corporate image, we always effort on best quality and service,

welcome to inquiry!

Fast answer and question:

1: Are You Trading Company or Factory?

Kowloon Machinery is a Factory with 31 years experience in machinery manufacturing; we provide you completive Factory Price and good After-sale Service!

2: What about the Machine Installation?

For a single machine or a simple line, we provide you Foundation Drawing ,Installation Instruction Books or successful installed machinery picture or video; for large machines and complex production line, we could send our engineers to guide the installation if necessary

3: How About the Spare Parts?

We offer some free spare parts like belt, gasket etc small parts, for the BLADES, KNIVES, SHAFTS etc important wearing parts, we suggest customers buy some along with the machines to save the shipping cost, and we have enough spares parts in stock.

4: What Will We Do If We Have Problems in Machine Working After We Buy the Machine?

Kowloon has people special for after-sale service,if customers outside China have problems when machine working, just feel free to send us the picture or video to show us, we will give you solutions in 24hours.

5: Could We Visit Your Factory and Test the Machine?

We warmly welcome you to visit our factory anytime, and we are very glad to test our machine with your raw material.